Increasing the reliability of engineering process simulations gathers five European countries in a Science and technology project

Nowadays, the use of numerical simulations has become a mandatory step in engineering design and material processing optimization. The simulation market for the automotive industry alone exceeds 1 B€. Despite the size of the market and the regular use of simulation in the engineering design industry, obtaining reliable input data, especially the description of the material behaviour at different temperatures and strains is a constant challenge and has not been fully answered yet. A solution to this problem is highly required for both the engineering simulation users and providers.

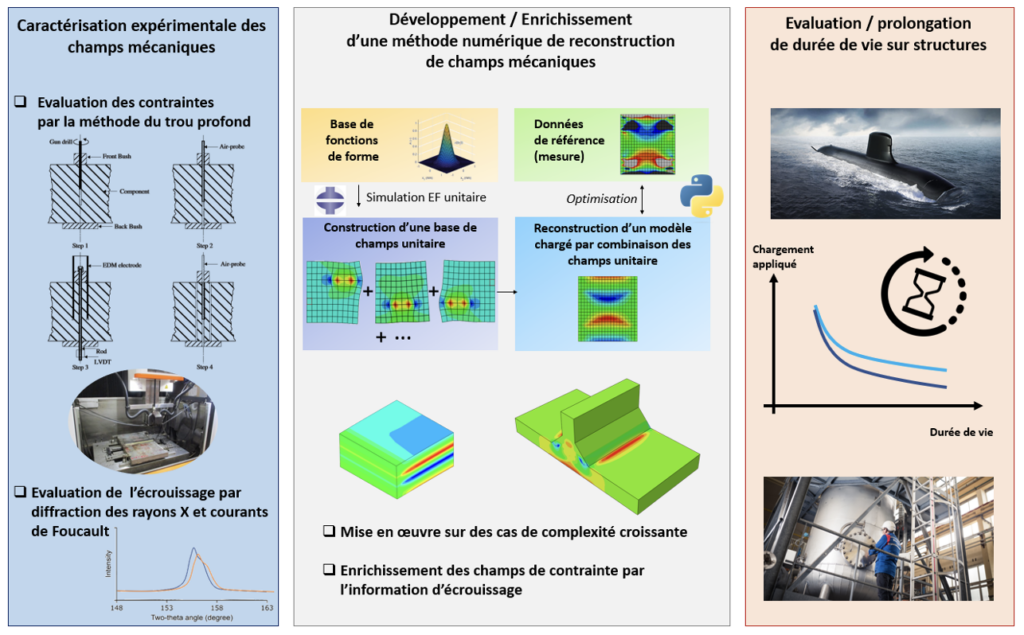

A European project that aims to improve the confidence, precision, and robustness of the numerical simulations of steels parts through the development of new techniques for the determination of reliable input data has started on the 1st of July 2020. The 2.5 M€ project gathers five European countries, four universities, three industrial partners, and more than twenty researchers for the next four years. The project entitled “Toward virtual forming and design: Thermomechanical characterization of advanced high strength steels through full-field measurements and a single designed test” has joined the Universities of Aveiro (Portugal – leader), Bretagne Sud (France), KU Leuven (Belgium) and Politecnica delle Marche (Italy) and the well-known companies MatchID and OCAS (Belgium) and DAF Trucks (The Netherlands) for the goal of developing procedures for the calibration of engineering material simulation software that would lead to stiffer, stronger, safer and lighter industrial parts. The EU contribution is through the research programme of the Research Fund for Coal and Steel – action RFCS-RPJ 2019.

Contact : sandrine.thuillier@univ-ubs.fr